SECURITY OF MANUFACTURING PREMISES

Security of manufacturing premises is a specific type of security requiring smart solutions, a unified system and clear security processes. This security type is one of the most popular in our company. We continuously develop and update our activity processes in order to ensure a high level of quality for our partners.

WE WORK WITH MANUFACTURING COMPANIES OPERATING IN VARIOUS MARKET SECTORS:

- Manufacturers of furniture and boards;

- Food industry;

- Fuel industry;

- Textiles industry etc..

In our years of working with manufacturing companies, we have noticed that the biggest problem for almost all of our clients in this arena is theft and non-existent (or ineffective) prevention methods onsite.

SECURITY OF MANUFACTURING PREMISES - ACTIVITY PRINCIPLES AND RECOMMENDATIONS

In order to significantly decrease the number of thefts and increase the safety of the company’s materials and equipment at manufacturing facilities/plants s we apply the following specialised processes:

- Inspection of the facilities perimeter. Most often we notice gaps in the security provided by the fences (the territory is not fully fenced off; the fence is damaged or has holes) or in non-fenced off passages (the territory has a couple of unprotected passages). In order for the security of the manufacturing facility to be effective, first of all, we recommend managing and fully securing the facilities perimeter.

- Inspection of the object’s visibility. Whole object should be visible in the security post, especially points of the object posing a higher risk. Prior to starting work, we always prepare the Security Audit, during which we identify the areas in which the security situation must be improved. Often, the current resources are enough for these solutions, it is enough to recalibrate or relocate the cameras.

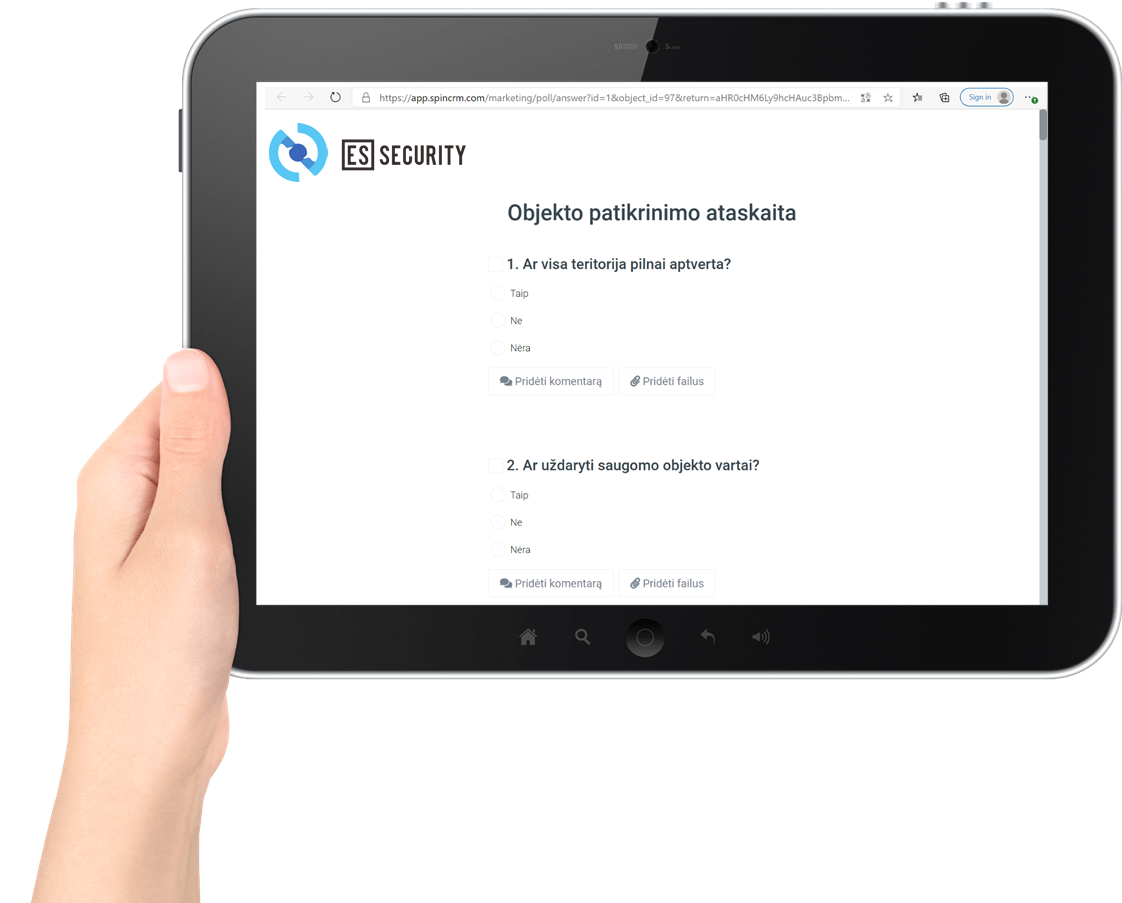

- Electronic journals. For some time, we have been using this useful monitoring tool in all facilities that we secure. The electronic journals can also be personalized in accordance to the needs of each client. We include important places that need to be monitored and all off the journals are accessible in real time for the representatives of our company and the client’s company. All of the information associated with security may be monitored in the electronic journals: visitor access logs, vehicle registration information, malfunction logs, infringements and the actions taken, vehicle weighing, recommendations for improving security and so on..

PATROLLING IN THE TERRITORY

In order to ensure the continuous patrolling in all of the territory, we use an electronic clocking system, which our prevention department staff actively monitor. The prevention department monitors whether the clocking and patrolling was performed at the predetermined time and whether the security officer walked through all of the predetermined points. When a point is missed, a promptly a message appears onour system.

UNSCHEDULED INSPECTIONS

These are conducted without any prior warning.We undertake inspections in these three categories: pedestrian traffic exiting the territory, vehicles driving out of the territory and the performance review of security officers whilst performing their role. . Non-scheduled inspections allow a more realistic appraisal of actual daily activity at a site and allows us to assess whether all of the security requirements are being adhered to and whether all of the compulsory functions are being performed.

FOUR EYES PRINCIPLE

During the loading or unloading of goods, it is recommended that at least two persons having different job descriptions participate, one of them - a security officer of our company. The Four Eyes principle provides better quality control, precise loading of the product, reducing chances of a mistake but also provides another level of monitoring and drives efficiency.

EMPLOYEE TRAINING

Each facilties is different; thus, our prevention department manager prepares employee training specific to site or objectives.. The employees are trained not only before commencing work but also throughout the process of cooperation - quarterly, bi-annually or in accordance to a specific need. We register each session training in the electronic security journals, wherein the employee marks areas, with which he/she was familiarized and trained. Security of manufacturing premises - is a sphere for which we have adapted specialized training for our staff aimed specifically to cater for the set types of companies.

HOW TO ENSURE EFFECTIVE SECURITY OF A MANUFACTURING PREMISES?

Security of a manufacturing premises and the effectiveness of it is a result achieved through mutual cooperation. Most often in manufacturing companies the security officers include themselves in daily activities; , thus it is essential to coordinate the functions of the employees as precisely as possible, and beforehand discuss the effectiveness of how things function currently. In order to achieve the maximum result, we always recommend performing security audit prior to starting work together.

The use of smart and electronic security systems with the help of which the security of manufacturing premises becomes more effective:

- Access control systems. Turnstiles and entrance to the territory with electronic cards are most popular types of access control systems. They are effective when there is a need to control a large flow of employees and visitors. This system also allows monitoring of who entered, where they entered and when they left.

- Access and vehicle weighing systems. In manufacturing sector, it is very important to control the produce being driven in and out. Special vehicle weight scales or smart video surveillance systems are used for this.

- Smart video surveillance system. This system can monitor the visitors and employees of the facility, the cars that drive in and out, the places of loading and critical points around the perimeter. Smart systems may monitor safety indicators necessary for your facility, promptly informing the security officer on the central monitoring display and the staff of your company about their breach.

- Fire safety systems. In the manufacturing premises, it is very important to install an effective and smart fire safety system, which would protect against unwanted losses. We often encounter situations wherethe fire safety system installed in the company is not calibrated, only part of fire safety sensors is operable, the system is not being tested etc. This greatly increases the risk and does not guarantee the effectiveness of the system.

The most effective type of security in manufacturing companies - COMBINED SECURITY, is when the security is ensured by a mix of manned security and smart security solutions.

INSUFFICIENT SECURITY OF THE PERIMETER OF THE TERRITORY

Insufficient perimeter security is a very common issue - the territory is not fully fenced off or the fences are damaged. Numerous times we have found pried-open fences, which were prepared for smuggling-out the goods. At first glance, such criminal activity might not be noticeable, because the culprits prepare for this very thoroughly. Which is why it is compulsory to perform the periodic inspection of the perimeter of the facility in question.

UN-MONITORED PARTS OF THE TERRITORY

A certain quality of electronic camera surveillance system is installed in almost every facility these days, but the quality, effectiveness and coverage of these systems is often poor due to poor camera maintenance, poorly aligned coverage maps or poor quality imaging. Bizarrely, it is not unusual to find no cameras in key areas such as loading docks and places of entry and egress.

FUNCTIONS OF THE SECURITY OFFICERS ARE NOT INSPECTED

You can check the functions of the employees by using various tools we make available, one of them - surveillance cameras installed at the posts. Our company also uses electronic journals, the information in which is accessible in real time. We are certain that the inspection of security officers is necessary not due to the lack of trust, but to analyze any problems that occur at the facility. The staff working there most often have the most insights about the necessary changes or problematic issues.

NON-OPTIMIZABLE RESOURCES

We notice that many companies have installed a variety of equipment, which either is not inter-connected or the functions are under utilised. After performing the audit, we will see how we can optimize the current resources of the company. If need be, we supplement the systems with additions or replacements and a bit of programming in order for the current resources to operate smoothly and interact better.

SECURITY OF MANUFACTURING PREMISES - REVIEWS OF CLIENTS

UAB „Nordnix“

“We have started working with the security service UAB “ES SECURITY” since 2019. After starting to cooperate with this security service we ascertained that qualified, accommodating and responsible security officers are working in the company. The employees of the company’s administration also operatively react towards the emerging issues or additional wishes. We want to recommend UAB “ES SECURITY” as flexible, operative and qualified security service for each business.”

UAB „Termopalas'

“We have started cooperating with the security service UAB “ES SECURITY” since 2018. We recommend this company as especially operative, qualified and client-centric security partner. Experienced staff is employed at UAB “ES SECURITY”, the employees are specialists of their area, ready to help and provide good quality services. We recommend the security service UAB “ES SECURITY” for a business, who wants to achieve mutually sound partnership.”